|

|

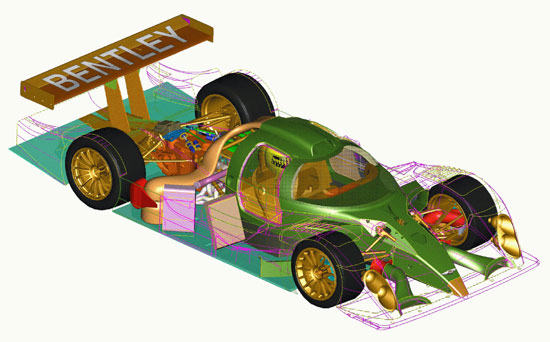

Team Bentley is proud to reveal details of the 2002-specification EXP Speed 8 Le Mans GT Prototype with which it will contest the famed 24-hours of Le Mans on 15/16 June.

At a first glance it might seem that little has changed from the car that last year drove through the worst Le Mans weather in living memory to claim third place overall. In fact every component has been analysed and then retained, revised or replaced as required. By the end of this process little more than half of the original components were retained for the 2002 design.

As in 2001, the EXP Speed 8 will be the only car in the LM GTP category for closed prototypes. The regulations differ principally from those that apply to the more commonly contested open prototype class by allowing a 1mm larger engine restrictor, but mandating two inch narrower tyres.

The brief handed down to Team Bentleyís designers for the 2002 car was to create a car, which retained the outstanding construction quality and reliability of its forebear, but to improve its already considerable dynamic abilities in every area. This meant more accessible performance, greater mechanical and aerodynamic grip, a more favourable downforce to drag ratio and better fuel consumption. Currently the car is on target to deliver every one of these critical considerations.

Engine

A new Bentley 4-litre twin-turbocharged V8 engine has been developed for the EXP Speed 8 to replace the 3.6-litre unit used last year. Unlike the earlier unit that was closely based on engines used by Audiís Le Mans cars, the 4-litre powerplant was commissioned by Bentley and designed to a unique and exclusive specification.

Perhaps surprisingly, the increase in engine size was not prompted by a desire for more power. Le Mans regulations stipulate that 4-litre cars use a smaller restrictor than those displacing 3.6-litre offsetting all possible gains in outright power. However, and as importantly, the 4-litre configuration offers the opportunity of creating more torque and spreading it over a wider area, so greatly enhancing the carís driveability. So impressive are the gains made here that, in testing, the drivers reported that the engineís characteristics were more like those of a large capacity, normally aspirated engine, than a small, turbocharged unit.

The advantages of being able to combine the driveability of a normally aspirated engine with the compactness and light weight of a turbo unit would be significant anywhere, at Le Mans they are likely to prove crucial. It means the engine will pull strongly from low revs and thereby save gearchanges on every lap, helping to preserve the transmission. Perhaps more importantly still, maximum power is developed at a much lower engine speed despite the fact that the engine will safely rev as high as its predecessor. This gives the driver the choice of changing up early and sparing the engine or, when heíd only be in the higher ratio for an instant, staying in the same gear and saving the gearchange.

The most important innovation in the engine is the use of direct injection or DI. Injecting fuel directly into the combustion chamber greatly improves engine efficiency, the most dramatic manifestation of which is better fuel consumption. Yet it is only with the huge advances made in modern electronics that the combustion control needed to make the system effective has been realised.

The team is understandably remaining tight-lipped as to just how much fuel is likely to be saved over the course of 24-hours, but itís safe to say that by staying out longer on each stint, the team anticipates saving a number of pitstops during the course of the race.

Gearbox

The Xtrac-supplied six speed semi-automatic gearbox used last year has run faultlessly throughout testing despite the extra strains put on it by the larger capacity engine. It will be retained for 2002, albeit with revised ratios to exploit the new engineís power characteristics.

Monocoque

Heavily revised in both construction and design to create a tub that is now lighter, stronger and safer.

Aerodynamics

Though the new engine is by far the most obvious change, the alterations to the aerodynamic package are no less significant. The entire aerodynamic performance of the car has been thoroughly analysed and extensive modifications made, resulting in a dramatic improvement in the all-important downforce to drag ratio.

The changes start right at the front where a shorter nose houses a more aggressive diffuser; and they continue all the way along the car to the back where a longer tail section has been fitted, complete with a shorter two-plane wing. The sidepods have been entirely revised both to work better with the front diffuser and provide more consistent airflow to the larger intercoolers. These modifications mean that almost all the bodywork, both on top and underneath the car, is new.

Suspension

The front suspension of the 2002 Bentley EXP Speed 8 is brand new and designed to provide not just more front end grip, but better feel to the driver too. Every major component from the wishbones, rockers and anti-roll bar system, to the torsion bars and dampers have been redesigned for 2002.

The rear suspension has been largely retained but with revised damping and linear rate rockers.

Wheels and tyres

Bentley has continued its partnership with Dunlop, the most successful tyre constructor in the history of the Le Mans 24-hours. For 2002 and after a lengthy winter test programme, Dunlop has produced entirely new constructions of tyre for the EXP Speed 8. Those at the front are now much stiffer and are mounted in wider OZ Racing wheels. At the back the size and construction has also changed to allow for the even greater demands that will be made upon the tyres by the increased level of downforce and longer driving stints.

Electronics

The most notable inclusions are electric power steering and a Tyre Pressure Monitoring System (TPMS). Last yearís car had unassisted steering and while the wet weather helped to reduce driver fatigue, it was felt that for the duration of a hot and dry race, power steering would greatly enhance the driversí comfort as well as making the car lighter and easier to drive. Power assistance is provided electrically, rather than hydraulically, saving weight and using fewer components, thereby enhancing reliability.

The TPMS system uses sensors mounted behind each tyre valve that measure the pressure and temperature of each tyre. This information is fed back to the carís central computer which analyses it, looking for any drop in pressure or increase in heat that is outside its pre-programmed parameters. If such a fluctuation occurs, it is possible that a puncture is imminent and a visual and audible warning will be made in the cockpit. Like all major functions, its data can also be viewed from the pits. TPMS not only helps prevent punctures and makes it much more likely that a car with a puncture will recover to the pits undamaged, rather more importantly it could prevent accidents.

A new Bosch 2.9 management system is used on the EXP Speed 8, while all the wiring looms have been redesigned and replaced.

During testing the car has shown considerable advances over last yearís model in all important areas. Nevertheless it is to be stressed that 2002 is very much a development year and primarily an opportunity to test new components and systems prior to the major push for outright victory in 2003.

|

Copyright ©2000-©2023 TotalMotorSport

|