|

|

A Gran Turismo For The 21st Century

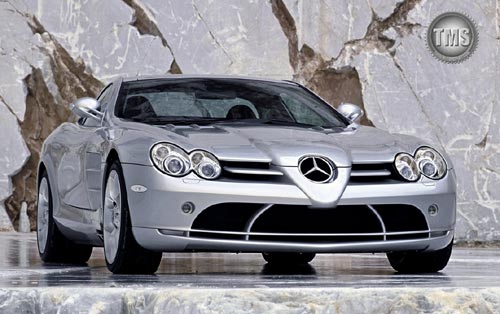

The new Mercedes-Benz SLR McLaren is an impressive testament to the competence and experience of Mercedes-Benz and our Formula 1 partner McLaren in the development and production of high-performance sports cars. The two-seater, with its striking swing-wing doors and styling elements borrowed from the Formula 1 Silver Arrows, builds on the legacy of the famous SLR race cars of the 1950s. Equipped with cutting-edge race car technology and groundbreaking new Mercedes developments, designed to ensure a high standard of safety and suitability for day-to-day use, the new SLR creates a distinctive image for itself as a 21st-century Gran Turismo – a thrilling synthesis of tradition and innovation.

The newly developed V8 supercharged engine delivers an output of 460 kW/626 hp and accelerates the sports car from 0 to 100 km/h in 3.8 seconds. The top speed is approximately 334 km/h. The body of the new SLR, like those of the Mercedes-McLaren Formula 1 race cars, is made from carbon fibre composites – lightweight materials which demonstrate exemplary energy absorption, hence ensuring the highest standard of occupant protection. The SLR is the world's first series-produced car to have a front crash structure manufactured entirely from carbon fibres. Adaptive airbags, newly developed kneebags and sidebags, belt tensioners, high-performance ceramic brake discs and an automatically adaptive airbrake in the boot lid round off the range of safety equipment on board the Mercedes-Benz SLR McLaren, setting new standards in this vehicle class.

Technology way ahead of its time and an abundance of power – these were the hallmarks of the legendary SLR race cars in which Fangio, Moss, Kling and other Mercedes drivers achieved spectacular victories in all of the major road races in 1955. The new SLR demonstrates the same characteristics, its groundbreaking technical innovations distinguishing it as the Mercedes-Benz among high-performance sports cars.

Two longitudinal members made from carbon fibre composite absorb energy in a head-on collision

The 21st-century Gran Turismo is made almost entirely from carbon fibre composite. This lightweight yet extremely rigid material originated in the aeronautical and space industries and has also proven its benefits in today's Formula 1 race cars. The weight advantage of the high-tech material over steel is around 50 percent, and the carbon fibres, on impact, are characterised by four to five times higher energy absorption than steel or aluminium. Mercedes-Benz exploits these qualities by incorporating two 620-millimetre longitudinal members made from carbon fibre in the front structure of the new SLR. These absorb the entire energy of the crash in a defined head-on collision, leaving the passenger cell largely undamaged. It is also made entirely from carbon fibre composite and therefore offers a very safe survival zone in side-on or rear-end collisions too.

Mercedes-Benz has introduced new material technology to the manufacture of the brake discs too. They are made from fibre-reinforced ceramic and are characterised by high fade-resistance and a very long life. In collaboration with the electrohydraulic braking system, Sensotronic Brake Control (SMC™), they allow outstanding deceleration figures too, impressively underlining the motor racing heritage of the Mercedes-Benz SLR McLaren.

460-kW/626-hp V8 powerplant with cutting-edge compressor technology

In the interests of optimum dynamic handling and high stability on braking, the new Mercedes-Benz SLR McLaren has a front mid-engined design. The high-performance V8 engine, mounted on a robust aluminium frame, is installed at a low level which allows a low centre of gravity for agile handling.

With its 5.5-litre displacement, the supercharged engine develops a peak output of 460 kW/626 hp and delivers its maximum torque of 780 Newtonmetres from 3250 rpm – a figure which remains constant across a broad engine speed range of up to 5000 rpm. This means that the SLR 8-cylinder is among the most powerful engines currently available in a series-produced roadgoing sports car. This high-performance car takes just 3.8 seconds to sprint from 0 to 100 km/h, it passes the 200 km/h mark after 10.6 seconds, and from a standing start it takes just 28.8 seconds to reach 300 km/h. The top speed is 334 km/h.

Water-type charge-air cooling, dry sump lubrication and four metal catalytic converters are further special features of this powerful engine – an engine which already meets stringent EU 4 exhaust gas regulations which are not due to come into force until 2005.

The 5-speed automatic transmission, fitted as standard, is also designed for high performance. It allows the driver to choose between three programs with different shift characteristics. When "Manual" is selected, the five gears can either be shifted using buttons on the steering wheel or using the selector lever's Touchshift function. In this mode the driver can also select between three shift stages – "Sport", "SuperSport" and "Race" – significantly shortening the shift times still further for an even sportier drive.

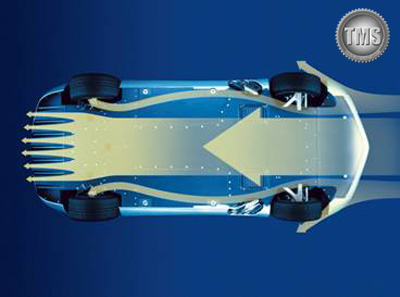

Aerodynamic concept uses expertise from the world of Formula 1

The body design of the Gran Turismo with the Mercedes star takes classical styling elements from the legendary SLR race cars of the 1950s and blends them masterfully with the sophisticated, avant-garde design language of both the latest Mercedes passenger car models and of the modern-day Silver Arrow race cars which took the McLaren Mercedes team to Formula 1 World Championship glory. The design's concept, in other words, thrillingly spans the divide between past and present, whilst at the same time showing the way forward for the sports car designs of tomorrow.

In order to meet the highest of standards in terms of handling at top speed, directional stability and the cooling air requirements necessary for high-performance cars of this kind, Mercedes-Benz worked with McLaren on developing this model's superlative aerodynamics, ensuring exemplary roadholding plus the on-road safety standards typical of Mercedes. Following extensive wind-tunnel tests, the Mercedes-Benz SLR McLaren was given a virtually smooth underbody with a special six-channel diffusor under the rear. Both features are familiar design principles from Formula 1. They ensure that the airflow beneath the vehicle is virtually unimpeded and that negative lift, or downforce, is produced at higher speeds. The distinctive sidepipes on each side of the vehicle are also the result of this high-performance sports car's aerodynamic underbody concept: a conventional exhaust gas system would have disrupted the smooth line of the underbody.

At the rear of the SLR an adaptive spoiler provides additional downforce. From a speed of 95 km/h, it automatically adopts a 10-degree position, increasing the contact pressure at the rear axle. The spoiler also doubles as an airbrake: when the driver brakes heavily, it rises to an angle of 65 degrees, not only ensuring increased aerodynamic drag but also shifting the aerodynamic centre further towards the rear. This lends the SLR excellent stability when braking from high speeds.

Functionality and luxury stylishly combined

It is the very high levels of practicality and luxury that truly make the interior of the SLR stand out. Individually padded carbon-frame seats, a multifunction steering wheel with race-car-type buttons for manual gear selection, clearly arranged chronometer-style instruments and high-grade materials define the atmosphere inside the high-performance sports car.

Alongside carbon and aluminium, the Mercedes designers have used "Silver Arrow" leather, specially developed for the SLR, which is available in the distinctive red of the legendary 1950s SLR race car.

Model Design And Equipment

Blending tradition and innovation

· Building on the sports car legend of the 1950s

· Making use of experience and expertise from the world of Formula 1

· Extensive standard equipment including the latest Mercedes innovations

SLR three spellbinding letters for car and motor racing fans. The abbreviation, which has come to represent the ultimate in thrilling car design, originally stood for "sporty", "light" and "racer". These were the principles behind the legendary race cars which Mercedes-Benz unveiled in 1955, their drivers spectacularly sweeping the board in the Mille Miglia, Targa Florio and the Tourist

Trophy.

Juan Manuel Fangio, Stirling Moss, Karl Kling, Count Berghe von Trips, Hans Hermann, Desmond Titterington and John Cooper Fitch sat in the cockpit of the SLR racer and made this Silver Arrow the most successful race car of the season. Eight cylinders, a 2982-cubic centimetre displacement, an output of up to 310 hp and a top speed of over 300 km/h – these were just some of the key figures behind the victorious race cars. Rudolf Uhlenhaut (1906-1989), then Head of Car Testing and Race Car Development at Mercedes-Benz, used them as his basis when he constructed a roadworthy coupé version which combined the design and technology of the gullwing 300 SL (in production since 1954) with the successful race car. The result was the 300 SLR Coupé – better known among connoisseurs as the "Uhlenhaut Coupé". At 290 km/h, it was the fastest roadgoing sports car of its day.

The new Mercedes-Benz SLR McLaren builds on these legendary models and aims to revive the passion for high-performance sports cars with the Mercedes star. Like its predecessor, the legendary "Uhlenhaut Coupé", the new swing-wing door vehicle brings groundbreaking technological developments from the world of motor racing to the road. At the same time it also revives the tradition of the Gran Turismo sports car and offers not only excellent performance but a high degree of safety, comfort, suitability for day-to-day use and exclusivity.

The blend of tradition and innovation has produced a masterpiece in terms of power and elegance. The Mercedes-Benz SLR McLaren impresses as much with its top power development and optimum handling as with its thrilling design and select appointments.

"Monocoque", "downforce" and other innovations from Formula 1

In order to ensure the exceptional status of a car with the revered SLR name, Mercedes-Benz and McLaren fed their extensive technical expertise from the field of motor racing into the development of the new high-performance sports car. For evidence, look no further than the front structures of the SLR, based on the high-strength monocoque constructions found in Formula 1 race cars, which – for the first time in a series-produced car – are made entirely from carbon fibre.

This sophisticated safety design is complemented by a braking system designed for high performance, with brake discs made from fibre-reinforced ceramic – a material which has also proven its benefits in the world of motor racing, with outstanding fade-resistance and top deceleration figures. In addition, the front mid-engined design of the new SLR allows the engine and transmission to be positioned near the centre of the vehicle, ensuring, in combination with a chassis design adopted from motor racing, optimum handling and an incomparable driving experience.

These latter qualities are also boosted by the 460-kW/626-hp high-tech powerplant, which was developed by Mercedes-AMG and clearly has motor racing in its genes. In it the SLR has one of the most powerful engines to be found in a series-produced roadgoing sports car. The world of motor racing was also the source for the "downforce"-based aerodynamic principle, with the six-channel diffusor on the underbody and the adaptive spoiler in the boot lid which doubles as an airbrake.

Thrilling Lines And Top-quality Equipment

The exciting design of the high-performance sports car was inspired by the Uhlenhaut Coupé and the current Formula 1 Silver Arrows. The long bonnet, taut midriff, rearward positioning of the passenger cell, short rear and swing-wing doors reflect the thrill of high speed. Inside the Mercedes-Benz SLR McLaren the designers have combined a stark sports-car look with a sense of extraordinary luxury. Select materials such as carbon, aluminium and top-quality, highly exclusive leather, specially developed for the SLR, dominate the passenger area of the Gran Turismo, underlining its exceptional quality.

The new SLR is also being launched with a number of other top-class technical features designed to raise safety and comfort to the highest level – ranging from the new kneebags and the powerful bi-xenon headlamps to the sophisticated sound system with its dynamic navigation facility. A selection of the long list of top-quality standard equipment features is provided below:

· Stowage compartments in centre console, between seats at rear and below rear shelf

· Adaptive airbags

· Aero windscreen wipers

· ASSYST PLUS active service system

· Aerial for car phone

· Anti-lock braking system (ABS)

· Outside temperature display

· Courtesy lights in doors

· Automatic tyre pressure monitoring

· "Audio 30 APS" car radio with CD changer and dynamic navigation system

· Car phone

· Bi-xenon headlamps

· Floor mats with SLR logo

· Brake Assist

· Electrically adjustable, single-piece carbon-frame seats, in three different sizes with interchangeable upholstery modules

· Anti-theft alarm system

· Electronic Stability Program (ESP®)

· Headlamp Assist

· Power windows

· 5-speed automatic transmission with three programs and choice of manual shift speeds

· Belt tensioners and belt force limiters

· Head/thorax sidebags in doors

· Interior lighting with night design

· Automatic child seat recognition

· Automatic climate control

· Kneebags

· Leather upholstery and leather interior appointments

· Light-alloy wheels

· Steering column, electrically adjustable

· Multifunction steering wheel with buttons for manual transmission control

· Fog lamps

· Rain sensor

· Trip computer

· Heated windscreen washer system

· Headlamp cleaning system

· ELCODE locking system

· Sensotronic Brake Control (SBCTM)

· Sound system

· TELEAID, TELEDIAGNOSIS and MB Info telematic services

· Cruise control with SPEEDTRONIC

· Touchshift

· TIREFIT with electric pump

· Central displays in instrument cluster

· Central locking with remote control

Design

Spanning the divide between the past, the present and the future

· Reinterpreting the styling elements of the legendary SLR race cars

· Twin-fin spoilers and arrow-shaped nose adopted from Formula 1 Silver

Arrows

· Distinctive twin-headlamp face of the latest Mercedes models

· Interior based around high-grade materials such as aluminium, leather and carbon

Legend and innovation — this is the precept underpinning the body design of the new Mercedes-Benz SLR McLaren, as it takes the classical styling elements from the legendary SLR racing cars of the 1950s and blends them masterfully with the sophisticated, avant-garde design language of both the latest Mercedes passenger car models and of the modern-day Silver Arrows race cars which took the McLaren Mercedes team to Formula 1 World Championship glory.

The design's concept therefore spans the divide between past and present and creates a car with a unique charisma – a Mercedes synthesis of legend and innovation which is impressive in every respect.

It is the front end in particular which singles out the new Mercedes-Benz SLR McLaren as a direct descendent of the racing cars which have been so successful in recent times: the centre is dominated by the distinguishing, arrow-shaped nose of the Formula 1 Silver Arrow, encompassing the Mercedes star at the front, an unmistakable hallmark of manufacturing origins that are steeped in tradition.

Underneath the nose can be found a further typical styling element taken from the Formula 1 race cars which took McLaren Mercedes to the World Championship crown in 1998 and 1999: the twin-fin front spoiler with the distinctively curved struts. As on the Silver Arrows, these aerofoil fins are more than just a stylish identifying feature, they are actually crucial to the car's aerodynamics. The high contact pressure they produce at the front axle plays a key role in the new SLR's sure-footed, race-car-like roadholding.

The fin design was adopted as a recurring feature of the SLR's exterior, thereby maintaining a high level of design consistency: finned sections also separate the headlamps from the nose, form the base for the two exterior mirrors and adorn the tail lights on each side of the car, where the indicators' LEDs are housed in two self-supporting fins positioned one above the other.

Mercedes Design Breeding: Twin-headlamp Face Forms Identifying Feature

Above the generously proportioned air intake for the engine cooling is the wide, flat bonnet, whose rear edge lies below the starting point of the A-pillars, permitting the deep-set design of the front windscreen. This is another typical element taken from the world of motorsport which gives drivers the level of visibility needed for high-speed motoring.

The headlamp arrangement is a refreshingly new version of the highly familiar and equally successful twin-headlamp face, which has been the calling card of

Mercedes-Benz passenger cars since 1995. In this SLR-style reinterpretation, although the dipped-beam and main-beam headlamps form a single unit, they nevertheless succeed in emphasising their basic, pronouncedly oval form. The design team has reinforced the powerful visual effect by sheathing the powerful projection headlamps in casings which resemble high-quality camera lenses, all housed behind clear glass.

As with all current Mercedes passenger cars, the oval lines of the twin-headlamp face form the starting points for modelling the bonnet and the wings. The rounded contours of the headlamps develop into powerful domed curves which quite deliberately evoke associations with the human anatomy: the curves extend back over the wings like the sinewy muscles of a trained athlete, leaving no doubt in anyone's mind that this car bristles with the pure power of a sporting superstar.

These contours — soft yet brimming with power and dynamism — combine with taut lines to produce a fascinating, sculpted exterior form, a clear expression of the uncompromising manner in which this car's high-performance credentials have been honed. The car flexes its muscles visibly but without any hint of aggression, with each fibre of its lithe body trimmed and tensed, ready to launch forward at any time.

The domed curves leading off from the inner pair of headlamps sweep seamlessly all the way back to the A-pillars, forming a smooth visual link between the front end and the passenger compartment. As they run up the long bonnet, the softly rounded domes again transform into taut, clean-cut lines, which in turn mould the appearance of the A-pillars and the side profile. This is also one of the elements underpinning the characteristic, powerful proportioning of the SLR silhouette: the long bonnet, taut midriff, compact passenger compartment and short tail create a deliberate association between the flow of the SLR's lines and the styling elements of Mercedes sports cars from years gone by, and symbolise the sense of forwards surge that courses through the new SLR.

The high-performance sports car exudes the same powerful, yet harmonious impression when seen from the rear too. This is down to the elegant way in which the lines flow from the passenger compartment into the lid of the boot, helped by the slender roof pillars which taper towards the bottom. Unlike the SLR Silver Arrows of the 1950s, whose tail curved gently downwards, the boot of the new SLR continues at the same high level in order to enhance the aerodynamic qualities.

The large tail lights are an immediate eye-catcher. The distinctive, triangular form of the transparent lenses, a typical feature of Mercedes passenger cars, has a wrap-around design which extends far into the side panelling to emphasise the width of the body.

Side Gills And Wide-opening Swing-wing Doors

It is above all the side profile of the high-performance sports car that identifies it as a car whose maker has a long and illustrious motor-racing tradition, with large, finned air openings breathing new life into the SLR legend. These "gills" are far more than a mere styling touch, serving now as they did back then to ventilate the engine compartment. The designers of the new SLR have lent further emphasis to this particular function by enlarging the surface of the fins towards the rear of the gills, and by placing a clean-cut line at the end of the fins which then sweeps further backwards to add to the styling of the swing-wing doors.

If there is one distinctive feature that the new Gran Turismo has adopted from the Uhlenhaut Coupé, the coupé version of the legendary SLR race car, designed in 1955 by Mercedes' head of testing at that time, Rudolf Uhlenhaut, it is the doors.

In their modern interpretation, however, they are attached to the front roof pillars rather than to the roof itself and swing forwards and upwards in a wide angle. No less sensational than the gullwing design from the 1950s, this new concept also enlarges the entrance to the vehicle to make getting in and out easy for both driver and passenger.

Functionality And An Inspiring Look Define The Interior Design

Inside, every detail of the interior reflects the high-performance character of the

Mercedes-Benz SLR McLaren. Take your place on board, and you'll feel the thrill of sitting in a thoroughbred sports car. The on-board atmosphere, however, is also one of safety and calm – key requirements where concentrated, fast driving is concerned.

The reason behind this is a straightforward yet very emotional design language. It takes up the fin design and continues it consistently in the interior. Here the typical SLR fins are reflected in the ventilation outlets, the airbags and the instruments. The profiles appear light and delicate, deliberately reducing the cockpit to the bare essentials, in keeping with motor racing philosophy. The design deliberately concentrates on the essential factor: the dynamic driving experience.

The focal point of the interior is undoubtedly the centre console with its high-grade aluminium trim. A visual extension of the distinctively shaped Formula 1 domes on the bonnet, the centre console serves as the transition between exterior and interior, whilst also picking up the powerful lines of the front-end design before they flow backwards over the transmission tunnel to the tail of the SLR. In order not to disrupt this clear-cut look, the radio and navigation system are inconspicuously housed below a cover in the centre console which opens in an elegant arc when pressed lightly. The instrument cluster surround also reinforces the impression of power. The two tubes appear to plunge into the bonnet, forming a visual link with the Gran Turismo's power source. Clearly designed, circular instruments are centrally located in these tubes and perfectly positioned in the driver's field of vision.

The design of the instruments is based on the look of a high-quality chronometer. The large dials are inscribed with letters specially developed for the Mercedes-Benz SLR McLaren. The rather stark appearance conceals the latest display technology.

Despite its motor racing character, the interior of the SLR also has a high-quality, inviting feel. This is thanks to the stimulating interplay of select materials. Aluminium and carbon contrast with supple "Silver Arrow" leather, which was specially developed for the new high-performance sports car and sets peerless standards in terms of its quality and material thickness. 20 different appointments colours are available to choose from, including the same bold shade of red which set new trends back in the 1950s when it was featured in those legendary, unforgettable sports cars, the SL and the SLR: the result is automotive tradition you can truly feel. A two-tone interior concept ensures both high functionality and an exquisite on-board atmosphere. In many areas the various materials are combined to create visual islands. A fine, haematite-coloured frame, for example, embedded in sumptuous leather, surrounds the aluminium centre console.

Bodyshell And Safety

High-tech materials for exemplary occupant protection

· Bodyshell and chassis made entirely from high-strength carbon fibre

· Carbon fibre composite crash elements with exemplary energy absorption

· Occupant protection featuring six airbags, belt tensioners and belt force limiters

· Sophisticated aerodynamic concept based on expertise from Formula 1

When it comes to body and safety technology the new Mercedes-Benz SLR McLaren yet again lives up to its reputation as an innovative force among today's Gran Turismos. High-tech materials from the field of aeronautical technology make their debut in a series-produced car here: carbon fibre is used for manufacturing the body, lending it its low weight and an exemplary rigidity and strength previously only achieved in Formula 1 race cars. The crash safety standards achieved using this innovative material are equally high.

Carbon fibre has been used to great effect in the aeronautical industry for some time. The rudder unit, vertical rudder, landing flaps and other parts of most airbuses are made from this material, in the development and series use of which the scientists at DaimlerChrysler Research played a significant role. Their expertise and the extensive experience of the Mercedes-Benz and McLaren experts in the field of race car design can now, for the first time, be seen in a series-produced car: the entire bodyshell and the doors, bonnet and chassis of the SLR are made from corrosion-resistant carbon fibre composite.

While offering the same strength as their steel or aluminium counterparts, carbon fibre components weigh up to 50 percent less than comparable steel components and up to 30 percent less than aluminium components. This makes carbon fibre composite the material of choice for manufacturing high-performance cars, because lower weight not only means lower fuel consumption but also outstanding transfer of power to the road. The lower the mass to be accelerated and braked, the better the agility. In fact, thanks to the extensive use of carbon fibre composites, the primary structure of the Mercedes-Benz SLR McLaren is around 30 percent lighter than the conventional steel construction of a comparable front mid-engined vehicle.

Carbon Fibre Composite Offers Significantly Higher Energy Absorption

On top of this, the state-of-the-art lightweight material is also characterised by very good energy absorption. The figures here for carbon fibre composites are around four to five times higher than those for metal materials. Formula 1 constructors have been exploiting this quality for several years, manufacturing the crash structure of their race cars from carbon fibre composite. The result has been a significant reduction in the risk of injuries being incurred in high-speed accidents in this top motorsport discipline.

The monocoque – or, to put it another way, the passenger cell – of the new

Mercedes-Benz SLR McLaren is also made entirely from this high-tech material. In the event of a head-on, side-on or rear-end collision, it offers the passengers a highly rigid and hence safe survival zone.

Carbon Fibre Crash Elements In The Front Structure

The innovative fibre composite demonstrates its safety advantages particularly impressively in the front structure of the SLR bodyshell. Here two conical carbon fibre composite elements, each approximately 620 millimetres in length and weighing just 3.4 kilograms, are enough to absorb the full energy of the crash in a defined frontal collision without exceeding tolerable deceleration values for the passengers. The carbon fibre composite members are bolted onto the aluminium structure of the engine mounts; at the front they are connected to the remaining bodyshell structure by means of a cross member and a horizontal sandwich panel made from carbon fibre composite. This makes the SLR the world's first series-produced car to have a front crash structure manufactured entirely from carbon fibre.

Aluminium engine mounts

Carbon fibre longitudinal member

Carbon fibre passenger cell

In a collision, the fibres of the carbon fibre composite elements shred from front to rear, absorbing the energy of the impact with constant deceleration. Thanks to this steady deformation behaviour, the energy absorption of the carbon fibre longitudinal members can be tuned to meet specific requirements. The engineers achieve this, for example, by creating a constantly changing cross-sectional area for the components. This fine tuning means that the deceleration values result not only in predictable energy absorption behaviour but also in a weight advantage, because this design uses only as much material as is actually needed.

The developers had to carry out countless tests and collate numerous findings before they managed to achieve this tailor-made, reproducible destruction behaviour. At the end of this process, which lasted several months, they were in a position to construct the material for the longitudinal members point for point and process it according to requirements.

The First Automated Production Of Carbon Fibre Composite Components

In order to manufacture complex components such as the carbon fibre composite longitudinal members for the front end of the SLR, the materials experts at Mercedes-Benz cast a glance at the work of their colleagues in the textile industry and adapted traditional manufacturing methods used in this sector, such as sewing, knitting, weaving and braiding, for processing high-performance fibres into high-strength structures. Series-production of the components required a high degree of automation where carbon fibre composite processing was concerned. While carbon fibre composites have, to date, been laminated by hand – a time-consuming process – the carbon fibre composite elements for the new Mercedes-Benz SLR McLaren are the first to be precision-made using state-of-the-art manufacturing facilities.

High-strength bonding and riveting techniques are used to connect the individual carbon components of the chassis and the bodyshell. The aluminium engine mounts are bolted to the carbon bulkhead and also bonded in place. The carbon structure includes integral metal link points for the aluminium and steel rear axle.

The high-performance sports car's groundbreaking safety concept includes a strict separation of the passenger compartment from the energy-absorbing impact zones. This is particularly clear at the front end: the carbon fibre composite crash elements are connected to the passenger compartment by robust aluminium frames which act as engine mounts. At the rear too the crash structure is separate from the monocoque. Two internal longitudinal members made from laminated carbon fibre and a robust cross member take on the task of energy absorption in the event of a crash – as a rule the passenger cell remains structurally unaffected.

In a side impact wide, deep door sills with multi-piece deformation elements made from specially reinforced carbon fibre composites and two aluminium profiles incorporated in the door protect the occupants. The robust frame of the SLR seat also has a protective function in a side-on or rear-end collision; it is also made from high-strength carbon fibre.

Retention System Featuring Adaptive Airbags, Sidebags And Kneebags

A cutting-edge retention system with six airbags, belt tensioners and belt force limiters completes the SLR's sophisticated safety concept, ensuring that it meets all Mercedes standards.

In the event of a head-on collision of a specific severity, the electronic control unit first triggers the high-performance belt tensioners, which pull up to 15 centimetres of loose belt taut in fractions of a second, reducing the forward displacement of the occupants caused by the impact. The Mercedes-Benz SLR McLaren is also fitted with kneebags, which – together with the two-stage driver and front-passenger airbags – provide a large protective cushion for the driver and passenger, supporting the effect of the seat belts and belt tensioners.

Upfront Sensors For Rapid Airbag Deployment

The belt tensioners are also activated if a roll-over situation is detected. A roll-over sensor reliably recognises this type of accident and supplies its data at lightning speed to the central control unit for the retention systems. The sensor is located on the centre tunnel.

Sophisticated sensors also allow adaptive control of the front airbags, which deploy according to the severity of the accident. If the sensors register a light head-on collision, they each trigger just one chamber of the two-stage gas generators, and the 64-litre driver airbag and 125-litre passenger airbag are deployed with lower internal pressure. If the sensors register a higher severity of accident, the electronics also trigger the second chamber of the gas generators and the airbags fill with higher pressure.

Two upfront sensors on the radiator cross member also assist this adaptive deployment of the retention systems. Thanks to their exposed installation position in the front structure, they detect the severity of the impact even earlier and more precisely. The deployment algorithm uses both this signal and the signal from the central crash sensor on the centre tunnel.

While the occupants sink safely into the airbags, the belt force limiters reduce the force of the belt on the upper body, decreasing even further the risk of light chest and shoulder injuries.

Sidebags Provide Extra Protection For The Head

Protection in the event of a side impact is optimised by integral sidebags in the doors. These cushion both the head and the upper torso and are sometimes, therefore, referred to as "head/thorax bags". In a side-on collision, this specially developed side airbag rips open a seam above the armrest and inflates in milliseconds to form an asymmetrical airbag, the upper edge of which, when inflated, extends higher than that of the familiar sidebag found in the Mercedes saloons. This design means that the air cushion reduces the risk of the head hitting the side windows or any object which may penetrate the interior. It also holds back glass shards and other objects which could enter the interior in a collision.

The automatic child seat recognition system, developed by Mercedes-Benz, is also part of the SLR's standard equipment. It deactivates the passenger airbag if a special child seat from the Mercedes-Benz accessories range is installed on the passenger seat. These child seats have a transponder system which receives and responds to signals from two antennae in the seat upholstery. As a result of the exchange of data, the airbag electronics recognise that a child seat is fitted and deactivate the airbag on the passenger side since its deployment is not desirable in these circumstances. The belt tensioner and sidebag remain activated, offering the young passenger additional protection in the event of an accident.

Swing-wing Doors With Large Angle Of Opening

If there is one distinctive feature that the new Gran Turismo has adopted from the Uhlenhaut Coupé, the 1955 coupé version of the legendary SLR race car, it is the doors. In their modern interpretation, however, they are attached to the front roof pillars rather than to the roof itself and swing forwards and upwards in a wide angle. This new concept ensures greater safety, an exciting look and, because of the large opening angle, allows comfortable access to the interior for the driver and passenger.

The high-performance sports car's luggage capacity is equally striking. The leather and velour-trimmed boot holds a total of 272 litres (using the VDA measuring method). Flaps below it provide easy access to stowage compartments for the washer and brake fluid reservoirs, the two batteries and tools. The designers opted for this unusual arrangement in order to achieve sports car-style weight distribution with a low centre of gravity close to the centre of the vehicle.

Newly Developed Metallic Paint

The Mercedes-Benz SLR McLaren's paintwork is also a special development. The water-soluble, environmentally compatible metallic paint was specially adapted for the carbon fibre composite body and is distinguished by larger metallic particles. In comparison with conventional car paints, this paint creates a particular effect of depth and a thrilling sheen. Every SLR sports car is painted by hand.

Aerodynamic Development Using The Latest Test Methods

In view of the considerable power of the Mercedes-Benz SLR McLaren, which is capable of speeds above 300 km/h, special attention had to be paid to the subject of aerodynamics. The focus was less on producing as low a cd value as possible than on ensuring safe and reliable handling at high speeds. It is vital that, when travelling at speed, the body does not generate lift but instead produces downforce, which ensures that the SLR remains firmly pressed to the road for optimum roadholding.

The Mercedes-Benz and McLaren specialists applied cutting-edge test and analysis methods to the process of achieving top aerodynamic performance. Groundbreaking aerodynamic tests, using scale-1:3 models, took place in the McLaren wind tunnel which is used to hone the Formula 1 race cars. Additional test runs in the University of Stuttgart's cutting-edge wind tunnel were also particularly helpful, allowing a realistic analysis of the airflow along and below the body.

While the wheels of test cars normally stand still in wind-tunnel tests, the Stuttgart facility allows the aerodynamic interaction between the road surface, the tyres and the body to be tested. Two steel conveyer belts drive the tyres, simulating all of the flow processes associated with travelling on ordinary roads or motorways. Using this facility during the development of the SLR, the Mercedes engineers were able to examine the influence the moving wheels have on drag and lift.

High Downforce For Perfect Roadholding When Travelling At Speed

As a result of these and other sophisticated wind-tunnel tests, the Mercedes-Benz SLR McLaren was given a virtually smooth underbody with special spoilers at the rear axle, diffusors at the front axle and a special six-channel diffusor at the rear. These features are familiar design principles from Formula 1. They ensure that the airflow beneath the vehicle is virtually unimpeded and that, depending on the speed, negative lift, or downforce, is produced. The distinctive sidepipes on each side of the vehicle are also the result of this high-performance sports car's aerodynamic underbody concept: a conventional exhaust gas system would have disrupted the smooth line of the underbody.

The effect is reinforced by an adaptive spoiler (known as an airbrake) on the boot lid of the SLR. From a speed of 95 km/h, the 1,000-cm2 component automatically rises to an angle of 10 degrees, exerting further pressure on the rear axle. It also acts as an additional airbrake: when the driver brakes heavily, the rear spoiler rises to an angle of 65 degrees, the significantly higher drag providing an additional braking effect. This lends the SLR outstanding stability on braking from high speeds.

In most situations the electronics control the airbrake as required. However, the driver can also opt to take control of the adjustments using the switch in the centre console, manually raising the rear spoiler up to an angle of 30 degrees. Depending on the angle of the airbrake, at 240 km/h a total downforce of up to 167 kilograms is created.

Thanks to the interaction of the fin aerofoils at the front of the vehicle, the smooth underbody, the six-channel diffusor at the rear and the airbrake, the Mercedes-Benz SLR McLaren offers an extraordinary aerodynamic balance which is reflected in the car's outstanding handling.

Frontal area A 2.032 m²

Coefficient Of Drag Cd 0.374

Drag area cc x A 0.76 m²

Coefficient of lift, front axle clfa - 0.05

Coefficient of lift, rear axle clra - 0.089

The distinctive sidepipes on each side of the vehicle are also a result of the high-performance sports car's aerodynamic underbody concept: a conventional exhaust gas system would have disrupted the smooth line of the underbody and the diffusor design.

Bi-Xenon Headlamps For Dipped And Main-beam Setting

The innovative light system also significantly boosts road safety. In twilight or in the dark powerful bi-xenon headlamps light up the road. With bi-xenon headlamps only one lamp is needed for dipped and main beam light. While the entire beam is used for the main-beam setting, a disc is inserted between the lamp and the lens when the dipped setting is selected, blocking out a section of the light beam.

With the main-beam setting the H7 spot in the inner headlamp of the distinctive twin-headlamp face is also activated. A dynamic headlamp range adjustment system, which automatically adjusts the angle of the light beam to the position of the body and compensates for momentary pitching on braking or accelerating, is also part of the sports car's standard equipment – as is Headlamp Assist, which automatically activates the exterior lights as soon as it gets dark or when the SLR enters a tunnel.

LEDs Deliver Twice The Intensity On Braking

The tail lights are based around state-of-the-art LED technology. The light diodes not only react around 150 milliseconds faster than conventional bulbs on braking but also have a significantly longer life. A total of 51 LEDs light up in each tail light when the driver switches on the exterior lights – on braking they illuminate with twice the normal intensity.

Interior

Harmony Of Forms And Materials

· Motor racing character with new dimensions in comfort

· Exciting cockpit design focuses on the essentials

· Top-class automatic climate control with sophisticated sensor system

· Top-quality radio, sound system and navigation system

The combination of luxurious appointments and a stark sports car-style feel creates a uniquely spellbinding atmosphere on board the Mercedes-Benz SLR McLaren. Exclusive, soft "Silver Arrow" leather, specially developed for the SLR, and select materials such as aluminium and carbon contrast strikingly with the pure functionality of a vehicle whose roots lie in the world of motor racing. In the interior, as in the exterior, the motor racing heritage is combined with the clear advantages of a classic Gran Turismo: outstanding ride comfort and a deliberate concentration on the pleasures of refined dynamic driving.

Despite its focus on luxury and comfort, the Mercedes-Benz SLR McLaren's interior dimensions are clearly those of a high-performance sports car. In keeping with extraordinarily high demands in terms of dynamic handling, the passenger cell is compact, creating a tailored feel. Nevertheless, there is a generous sense of space inside the two-seater, thanks, in part, to the deep seat position, which allows a low roof line, at the same time lowering the centre of gravity, which benefits dynamic handling. The backrest of the carbon fibre seat is set at an angle of 28 degrees to the seat cushion, rather than 25 degrees, in order to allow a sporty seating position.

Generous dimensions ensure an attractive interior. The SLR exceeds the shoulder and elbow width dimensions of many luxury and mid-class saloons, providing its occupants with plenty of personal space. The key interior dimensions of the Mercedes-Benz SLR McLaren:

Interior length* 1006 mm *from the accelerator to the seat reference point in the rearmost seat position

Headroom 919 mm

Shoulder-height width 1371 mm

Elbow width 1443 mm

Seat cushion height 565 mm

Interchangeable Seat Cushions For An Individual Fit

Having entered through the wide-opening swing-wing doors, the driver and passenger take their places on light, single-piece carbon fibre seats, the basic design features of which have proven their benefits in the world of motor racing. Thanks to the multi-layer carbon fibre composite structure, they are not only 25 percent lighter than conventional car seats but also offer ergonomic advantages: a set of two upholstery modules, in three different sizes, allows the seat contour to be adapted individually to the anatomy of the driver. Three sets of these side upholstery modules are available, ensuring that the seats can be adapted to the optimum upper body and hip width for the driver, providing made-to-measure lateral support. The individual modules, upholstered in semi-aniline leather, are bolted onto the carbon frame.

The single-piece carbon fibre composite frame is connected at four points to an electric seat adjustment mechanism, which is used to adjust the seat's fore-and-aft position (by 130 millimetres), height (by 41 millimetres) and angle (up to 9.6 degrees) according to personal requirements. As a result of the single-piece design of the carbon fibre composite seat frame, the angle of both the seat cushion and the backrest are adjusted simultaneously.

High-class Chronometer Look For Cockpit

Even the process of inserting the electronic ignition key has been imbued with an enthralling, uniquely SLR feel: a starter button on the solid metal shift knob at the top of the gearshift lever on the centre tunnel instantly begins to glow red. Apply slight pressure with your thumb, and the grid-style flap opens to provide access to the illuminated button. One press with your thumb brings the tremendous power of the V8 supercharged engine to life.

The interaction of various well-designed details in the interior underlines the thoroughbred character of the SLR at all times. Nevertheless, the cockpit design deliberately focuses on the essentials, in keeping with motor racing philosophy. Easily readable characters on a dark background, which were specially created for the SLR, define the instruments' attractive, classic chronometer design – a design which, even at first glance, signals outstanding precision. They are enclosed by a matt chrome surface and are flanked by further displays, indicating the coolant temperature (left) and tank capacity (right), plus pilot lights and warning lights which only light up when the ignition is started or if there is a fault.

The brightness of the backlit dials automatically adapts to the prevailing light conditions in the interior of the swing-wing-door vehicle. A further unusual detail: when the engine is started, the needles spring back to their home position.

Cutting-edge displays in the lower section of the speedometer and the rev counter serve as an information centre for a number of functions. The aim of this control and display concept is to inform the driver of the operating status of the car without diverting his or her attention from the road. The two central displays are coupled both with the multifunction steering wheel and with the car radio, the telephone and the navigation system – which means that, at the touch of a button, the driver's personal list of stations, the selected CD, the telephone directory or navigation information appears directly in the driver's field of vision.

Multifunction steering wheel with buttons for quick gear changes

Eight illuminated buttons on the multifunction steering wheel allow the driver to specify his or her requirements – a light tap with the thumb is all it takes. They provide a simple means of regulating the volume and of accepting or terminating phone calls.

The three-spoke steering wheel, which has a diameter of 380 millimetres, was specially designed for the Mercedes-Benz SLR McLaren. It can be adjusted for reach by 60 millimetres and its height can be varied by 2.7 degrees. On the back of the spokes are buttons which the driver can use to change gears in Manual mode without having to take his or her hands from the wheel – a familiar feature in Formula 1.

Aluminium console with buttons for airbrake and shift program

The centre console, made from high-grade aluminium, is a further eye-catching feature on board the high-performance sports car. It houses not only the car radio with its navigation system, but the climate control unit and several new switches too, which activate and control various innovative technological features on board the SLR.

One of these switches operates the airbrake on the boot lid. From a speed of 95 km/h this automatically extends to provide more downforce, and when slowing down it rises to a steep angle to ensure optimum deceleration. The SLR driver can also use the switch here to position the airbrake as required.

The two rotary switches on the centre console are a further unusual feature. They can be used by the driver to select between the automatic transmission's three different shift programs: "Manual", "Comfort" and "Sport". The driver can also use the right-hand rotary switch to determine the speed of the gearshifts.

The radio and navigation unit are also accommodated in the centre console, concealed by an aluminium flap so as not to distract the driver. Beneath the radio/navigation unit are two ergonomically placed aluminium rotary switches for controlling the air conditioning system.

Material concept underlines elegance and sportiness

In the two-tone interior, which uses only select materials such as high-quality leather, fine Alcantara for the entire roof trim and elegant pearl velour for the carpets, the dashboard is dark in order to prevent irritating reflections while the seats, door panels, tunnel trim, rear wall console and the rear shelf panel come in a contrasting colour.

There are plenty of inspired details: the high-quality integral loudspeakers in the door panels, for example, have a grid-form cover which echoes the styling of the air outlets on the sides of the vehicle. The rear of the grid surround forms the door handle, while a simple leather loop in the upper area of the door serves as a separate door pull – a traditional feature derived from the legendary Mercedes-Benz motor racing vehicles. The uncompromising, clean-cut interior of the Mercedes-Benz SLR McLaren also features aluminium pedals with rubber studs.

Large boot and roomy stowage compartments

An exceptionally large, saloon-style boot underlines the fact that this is a thoroughbred Gran Turismo, designed for long-distance travel. According to the VDA measuring method, it has a capacity of 272 litres. Even when the luggage compartment is fully laden, the occupants are still assured unimpeded access to the CD changer, which is housed in the boot.

In addition to the spacious boot, there is plenty of stowage space in the interior – a total of 46.1 litres, including a 42.5-litre compartment below the rear shelf. Further stowage compartments can be found in the rear wall and console of the centre tunnel.

The switches for adjusting the seats, the power window buttons and the door release are positioned within easy reach between the door sill and the seat, providing a further example of the sports car's consistent use of space and ergonomic design. The handbrake is located in a moulded recess to the right of the centre tunnel.

Automatic climate control with sensors which register the position of the sun, the air quality and humidity

Despite its uncompromising motor-racing character, the Mercedes-Benz SLR McLaren is fitted with a state-of-the-art climate control system, which offers the ultimate in power, functionality and controllability. The two easy-grip aluminium dials on the air conditioning control unit in the centre console allow separate temperatures to be selected for the driver and passenger side – the set value is illuminated on the aluminium dial.

In automatic mode, a microcomputer monitors the functions of the automatic climate control system, receiving and processing a whole range of data. This includes information on the battery voltage, coolant temperature, engine speed and road speed plus the position of the doors and the side windows. Sensors supply further key readings:

· Two sensors continuously record the temperature in the interior.

· A solar sensor on the dashboard measures the angle of incidence and intensity of the sun's rays so that the temperature, quantity and distribution of the air blown into the interior can be regulated appropriately.

· A dew point sensor in the air conditioning system's intake duct registers humidity and allows economic regulation of the refrigerant compressor.

· A pollutant sensor in the automatic climate control system's intake channel detects any increase in the concentration of carbon monoxide and nitrous oxides in the incoming air. If an increase is detected, the system automatically switches to recirculation mode.

Like the automatic climate control system in the SL-Class sports car, the system on board the SLR operates according to the reheat principle: depending on its humidity, the incoming air is first cooled and in the process dried so as to ensure mist-free windows. Only then is it passed through the heating element and heated to the desired temperature.

Sophisticated lighting concept for the interior

One of the air conditioning system's sensors, which records the interior temperature, is accommodated in the overhead control panel. The panel also houses the switches for several of the lights which make up the sophisticated interior lighting concept.

Special features include lights below the sun visors which automatically switch on as soon as the visor is folded down and the vanity mirror opened. There is also a reading light which is installed in the interior mirror, and the doors each feature a round lens-shaped light which illuminates the door sill area when the doors are opened. The intensity of most of these lights is automatically regulated according to the ambient light conditions.

Specially adapted audio and navigation system

The Mercedes-Benz SLR McLaren is equipped with a top-class communication system which has been adapted to the requirements of a high-performance sports car. The Audio 30 APS car radio combines a radio and a cassette player plus the controls for the CD changer and the dynamic-route-guidance navigation system in a single unit. It has a clear design, is easy to operate and its functions are displayed in the speedometer and the rev counter – which means that the driver can concentrate on the driving rather than searching for information in excessive detailed displays.

The optimum sound quality comes courtesy of the Bose sound system, which has been specially attuned to the SLR. It uses a total of seven loudspeakers and sophisticated electronics, and not only compensates for interference but also has a microphone which constantly registers driving noise and adjusts the volume accordingly, without the driver having to intervene.

Other integral features include the permanently installed mobile phone system and all of the aerials which are required for radio and telephone reception and for operating the satellite navigation system.

Telematic functions for accidents or breakdowns

SLR drivers also benefit from new traffic services with this cutting-edge communication system. The following highly effective telematic functions are available:

· TELEAID is an automatic emergency call system which, in the event of an accident, sends out an SOS signal to alert the emergency services and lead them to the scene of the accident. The emergency call is either triggered via a crash sensor or by pressing a button in the overhead control panel. At present TELEAID functions in Germany and the USA.

· TELEDIAGNOSIS makes contact with Mercedes-Benz's central Customer Assistance Centre (CAC) at the touch of a button on the car phone headset, at the same time informing the centre of all necessary vehicle data and the precise position of the car. This means that service personnel can be directed to the vehicle quickly and precisely. TELEDIAGNOSIS is available in Germany.

· MB Info is a service which offers Mercedes customers the opportunity, using the TELEAID technology, to direct general questions to the customer advisors at the Customer Assistance Centre. One touch of the "Info" button is all it takes to establish a free call. This service is currently offered in Germany and will be extended to other countries in the future.

Engine And Transmission

8-cylinder powerplant with motor racing in its genes

· V8 engine with 460-kW/626-hp output and 780-Newtonmetre torque

· Metal catalytic converters for low exhaust gas emissions in line with EU 4 standard

· Sidepipes reminiscent of 1950s SLR models

· 5-speed automatic transmission with 3-stage manual shift program

An abundance of power and high-tech features from the world of motorsport – these are the defining characteristics of the V8 engine in the Mercedes-Benz SLR McLaren. Which means that the first 8-cylinder to be completely developed by

Mercedes-AMG fits perfectly into the high-performance concept of the new

Gran Turismo.

When developing the powerplant, the AMG engineers applied both the expertise they had acquired during their three-decade involvement in motorsport and the stringent standards of the Mercedes-Benz brand. After an extensive concept phase, they decided in favour of an 8-cylinder design with a 5.5-litre displacement, a cylinder angle of 90 degrees, a screw-type compressor and a crankshaft supported by five bearings.

The result is impressive: from a mere 1500 rpm, the SLR powerplant delivers torque of over 600 Newtonmetres, rising to 700 Newtonmetres at 2000 rpm. The maximum of 780 Newtonmetres is available from 3250 rpm and remains constant in a broad engine speed range up to 5000 rpm. The supreme torque curve is coupled with the agile response of a sporty engine which never denies its high-performance character. Figures such as 460 kW/626 hp at 6500 rpm – an extraordinarily high engine speed for this displacement size – speak a powerful language.

As the figures indicate, the new SLR is endowed with what is currently one of the most powerful engines to be found in a series-produced roadgoing sports car.

An overview of the key data:

Cylinder arrangement: V8

Cylinder angle: 90o

Valves per cylinder: 3

Displacement: 5439 cc

Bore/stroke: 97.0/92.0 mm

Cylinder spacing: 106 mm

Compression ratio: 8.8:1

Output: 460 kW/626 hp at 6500 rpm

Max. torque: 780 Nm at 3250-5000 rpm

Engine weight: 232 kg

Power/weight ratio: 2.0 kW/kg

With this much power under the bonnet, the SLR's performance figures are among the best in its class:

0–100 km/h (0-62mph): 3.8 s

0–200 km/h (0-124mph): 10.6 s

0–300 km/h(0-186mph): 28.8 s

Top speed: 334 km/h

Fuel consumption is 14.8 litres per 100 kilometres (NEDC combined consumption, provisional figure).

Power from screw-type compressor

To ensure good cylinder charging, the engine has a mechanical compressor with two screw-type aluminium rotors which, in the interests of low friction losses, are Teflon-coated.

The charger is so compact that the engine specialists were able to install it between the two cylinder banks of the V8 powerplant. Despite the space-saving design, its innovative technology allows a significantly higher charge pressure than conventional mechanical chargers because the two rotors achieve a top speed of around 23,000 revs per minute, forcing air into the air inlet of the 5.5-litre powerplant at a maximum pressure of 0.9 bar. This means that they compress around 1850 kilograms of air into the eight combustion chambers per hour – which is up to 30 percent more than the figure achieved by rival charging systems.

In order to ensure the greatest possible efficiency, the AMG engineers created an intelligent engine management system which regulates the operation of the screw-type compressor according to the engine speed and load. This means that the charger is only active when it is needed. Nevertheless, the system ensures that the maximum output is available as soon as the driver calls it up by stepping on the accelerator. When this occurs, the electronics of the engine management system trigger an electromagnetic coupling which immediately activates the compressor, which is powered by a separate poly-V-belt. Because the charger delivers its output in fractions of a second, even the most perceptive driver will not notice the phases without charger support. The charger system's air recirculation flap, opened under partial load, helps reduce fuel consumption.

Two charge-air coolers with separate water circuit

In addition to the compressor, the electronics also monitor all other variables relevant to the engine – both the powertrain management for the pedal-dependent drive characteristics and the implementation of spontaneous transmission or ESP® interventions. They also ensure optimum control of the water circuit for the charge-air cooling system, as efficient charge-air cooling is essential where high output is concerned. This is because cold air is denser than warm and also contains significantly more oxygen for combustion. In the Mercedes-Benz SLR McLaren's V8 engine, two separate charge-air coolers are responsible for this key task – one per cylinder bank. This ensures that loss of pressure is very low.

The highly effective engine-based charge-air coolers operate along the lines of an air/water heat exchanger: the air, compressed and hence warmed by the compressor, is cooled via a separate water circuit – making the process independent of the temperature outside. This means that the 8-cylinder can deliver its maximum output and torque spontaneously at any time.

The high performance figures of the 8-cylinder engine in the new SLR, however, not only demand good cooling of the combustion air but also result in an overall increase in engine cooling requirements. The engineers met this need by incorporating generous cooling air inlets and outlets and a powerful 850-Watt suction-type fan.

Crankcase with dry sump lubrication

The Mercedes-AMG GmbH engineers also applied their extensive experience in the world of motorsport and in the design of high-performance engines to other details of the SLR powerplant. The entire engine housing, for example, and the lower section of the closed crankcase are cast in aluminium and have special reinforcement ribs which make them particularly light. Each crankshaft is finely balanced and is supported by five bearings made from a highly durable material, allowing long-term transfer of the impressive forces from the compressor engine.

The pistons are forged and are therefore only manufactured in minimal numbers. Like the forged lightweight conrods, they are precisely measured and weighed and allocated to the individual engines in such a way as to produce minimal balancing tolerances. The pistons move in highly robust, wear-resistant and friction-optimised walls made from a special compound which is otherwise only used in motor racing. Dual oil injection effectively cools the pistons.

The design of the powerplant's oil cooling system is also based on experience gathered in the world of motor racing: a sophisticated dry sump lubrication system with an oil capacity of around eleven litres, combined with a five-stage oil suction pump and a two-stage oil pressure pump, ensures reliable lubrication under all on-road conditions. An important side effect of this technology is that, because of the dry sump lubrication, usually only used in motor racing vehicles, the engine is less tall and can therefore be installed at a lower level, allowing a low centre of gravity which benefits dynamic handling.

Following the usual practice at Mercedes-AMG, each SLR engine is manufactured by hand. In order to achieve the highest quality, the principle of 'one man, one engine' is applied. This means that each powerplant is the responsibility of one AMG engineer, who carries out the entire engine assembly process – from installing the crankshaft in the engine block and assembling the camshafts and the compressor to cabling.

Powerful high-pressure pumps in the tanks

The SLR's high-performance engine draws its fuel from two interconnected aluminium tanks. They are installed at a relatively low level to the left and right of the rear axle in order to keep the centre of gravity as low as possible to further enhance dynamic handling. The tanks, which have an overall capacity of 97.6 litres – of which twelve litres form the reserve – are equipped with two integral high-pressure fuel pumps. These are controlled by the engine management system and ensure that the fuel supply matches the engine speed and load. Here too a highly effective, SLR-specific solution was developed: one pump operates constantly while the second is only activated as required. At high output, they can pump a combined total of up to 310 litres of fuel an hour.

Four metal catalytic converters for efficient emission control

Where the engine is concerned, secondary air injection and dual ignition create the criteria required for low exhaust gas emissions. A sophisticated exhaust gas system complements these measures: the cascade-design twin-pipe system consists on both sides of a bulkhead-mounted catalytic converter and a main catalytic converter with a special noble metal coating, accommodated in the same housing. The state-of-the-art metal design allows extremely thin wall thicknesses and therefore a very low exhaust gas backpressure. Thanks to its cutting-edge technology of its engine management and emission control systems, the new SLR's 8-cylinder engine already meets the stringent exhaust gas limits stipulated by EU 4 plus the current US limits.

On each side of the vehicle the catalytic converter housing opens into a rear silencer which, just behind the front wheels, flows into two stainless steel pipes with a diameter of 60 millimetres. These sidepipes – a further reminder of the 1950s SLR racers – allow the smooth-surfaced underbody, which plays a crucial role in producing the new Mercedes-Benz SLR McLaren's first-class aerodynamic properties.

The silencers are folded several times in precisely calculated acoustic sections which produce the thrilling characteristic engine sound of the Mercedes-Benz SLR McLaren. The capacity of each silencer is 19.6 litres.

Manual transmission program for impressively short shift times

The five-speed automatic transmission, developed by Mercedes-Benz and already successfully used in several exceptionally powerful models, is also designed for high performance. It has been specially optimised for very high torque and also offers the driver the option of choosing between different shift characteristics. The transmission transmits the engine power via a finely balanced aluminium and steel powertrain to the differential and the rear axle.

The Speedshift system, developed by Mercedes-AMG for sporty driving, offers even more functions in the new SLR. The driver can decide, for example, whether to leave the shift work to the automatic transmission or to shift gears manually. He or she can also select the shift speed, determining how sporty the gearshifts are.

A rotary switch in the centre console offers a choice of three settings: "Manual", "Comfort" and "Sport". The activated programme is indicated in the instrument cluster display by the letters "M", "C" or "S". "Comfort" and "Sport" are automatic shift programs which, as the names indicate, place the emphasis either on comfort or on a more sporty drive.

In "Manual" mode, on the other hand, the driver can select the five gears either using the buttons on the steering wheel or using the Touchshift function on the selector lever. He or she also has the option of choosing between three shift stages for a sportier driving style:

· Stage I = "Sport"

· Stage II = "SuperSport"

· Stage III = "Race"

In the sequence indicated here, the response, reaction and closing times of the couplings in the automatic transmission, and hence the shift processes themselves, become increasingly shorter.

Chassis

Top performance for the race track and the road

· Aluminium chassis based on motor racing expertise

· High-performance brake discs made from carbon fibre-reinforced ceramic

· Electrohydraulic brake system (SBC™) plus rear airbrake

Highly developed motor racing technology, high-performance control systems and cutting-edge materials – a unique combination which propels the Mercedes-Benz SLR McLaren into a new dimension in sports car dynamics, helping it to achieve top figures in three key areas: agility, active safety and comfort. In the process, the SLR chassis meets every criteria a discerning car driver would expect to find in a Gran Turismo with a Mercedes star.

The axle design bears the signature of experienced racing car developers, with double wishbone suspension at the front and rear. The lower struts are arranged so that, as the springs compress and when cornering at speed, the wheels have a negative camber. This ensures the best possible contact with the road in every situation. At the same time the axle technology prevents the front of the car from diving when braking heavily and the rear from diving when accelerating.

Aluminium was the ideal material for the developers of the new Mercedes-Benz SLR McLaren's chassis. The wishbones are made from forged aluminium, while the wheel mounts are cast in aluminium. In addition to a whole series of other advantages over conventional steel designs, the lightweight nature of the material allows the chassis to react significantly faster and to respond more sensitively.

The relatively long wheelbase (at 2700 millimetres) also contributes to the SLR's exemplary handling and makes itself noticed above all in the car's outstanding directional stability, while the large track width, combined with the low centre of gravity, allows high cornering speeds. The key data at a glance:

Wheelbase: 2700 mm

Track width, front: 1638 mm

Track width, rear: 1569 mm

Turning circle: 12.2 m

Tyre size: Front 245/40 ZR 18 Rear 295/35 ZR 18

Wheel size: Front 9 J x 18 Rear 11.5 J x 18

Springing/damping combinations at the front and rear axle and a stabiliser at the front complete the chassis structure. The stabiliser is positioned above the front axle and – as in Formula 1 – is controlled via rocker arms. This means that it does not take up any installation space which could impair the smooth line of the underbody – a vital factor when it comes to the sports car's outstanding aerodynamic properties.

The speed-sensitive rack-and-pinion power steering also corresponds with the intelligent lightweight concept. In comparison with other steering systems, this design is characterised by a significantly lower weight. Thanks to its low installation position in front of the engine and the gear ratio of 12.6, the steering system responds directly to the driver's commands and carries them out with high precision. The three-spoke steering wheel has a diameter of 380 millimetres and is fitted with an electric motor which allows it to be positioned to suit the individual driver. It can be adjusted by 60 millimetres for reach, and the height of the steering wheel can be varied by 2.7 degrees.

SBC™ and ESP® for sporty dynamic handling with a high level of active safety

The electrohydraulic braking system, Sensotronic Brake Control (SBC™), a milestone in car technology, forms part of the standard equipment of the Mercedes-Benz SLR McLaren. It processes data from various sensors regarding the current status of the vehicle and can use this to calculate and apportion the optimum brake pressure for each wheel at lightning speed. A high-pressure accumulator holds the brake fluid, which flows into the system at a pressure of 140 to 160 bar. This also optimises the function of the Electronic Stability Program (ESP®), which keeps the SLR safely on track by applying targeted brake impulses to the individual wheels and/or reducing the engine torque. Here too SBC™ offers the advantage of higher dynamism and precision: thanks to even faster and even more finely metered brake impulses from the SBC™ high-pressure accumulator, ESP® can stabilise a swerving vehicle comfortably at an early stage.

The coordination of this system with the Electronic Stability Program (ESP®) was a particular challenge for the engineers of the high-performance sports car. Their aim was to adapt the dynamic handling control system to the vehicle's distinctly sporty performance yet maintain the usual safety standards, achieving an ideal compromise between outstanding dynamic handling and exemplary directional stability. Here too SBC™ demonstrated its strengths, being able to deliver adequate braking power at lightning speed in every on-road situation, thanks to its sophisticated sensors and the high-pressure accumulator, making a key contribution to the precision stability of the SLR. It was therefore possible to allow a very sporty driving style with controlled side-slip angles in keeping with the character of the high-performance car without compromising active safety.

On top of this, SBC™ significantly enhances active safety in critical situations:

· Emergency braking: SBCÔ recognises the driver's sudden switch from the accelerator to the brake as an indication of an emergency situation and is able to react automatically. With the aid of the high-pressure accumulator, the system increases the pressure in the brake lines and positions the brake pads against the brake discs so that they can grip with full force the moment the driver steps on the brake.

· In the wet: through brief, regular application of the brakes, Sensotronic Brake Control ensures that the film of water on the brake discs is stripped away so that the brakes can always operate to full effect. This automatic drying function is activated whenever the windscreen wipers have been operating for a certain length of time. The finely metered brake impulses are not noticeable to the driver.

· Braking on bends: thanks to variable brake force distribution, SBC™ is able to exert an active influence over the sports car's self-steering behaviour. While conventional braking systems always apply the braking pressure to the wheels on the inside and the wheels on the outside of the bend in the same ratio, SBC™ can distribute the brake forces to suit the situation. The system automatically increases the brake force at the wheels on the outside of the bend because, thanks to the higher wheel contact forces, they are able to transmit greater braking forces. At the same time the braking forces at the wheels on the inside of the bend are reduced to benefit lateral traction, which is so important to directional stability. The result is more stable braking behaviour and excellent deceleration figures.

Sensotronic Brake Control also offers special additional functions for even greater safety and comfort:

· The Soft-Stop function allows the vehicle to come to a particularly gentle stop, which will be much appreciated in city traffic, involving frequent stops at traffic lights. It is made possible by finely metered pressure control. The Soft-Stop function is permanently activated; only on emergency braking and when manoeuvring does the system ensure that priority is given to rapid deceleration.

· Start-Off Assist (SBC™ Hold) prevents the car from unintentionally creeping forwards or rolling backwards on hills and steep gradients. A brief but firm application of the brake pedal is all it takes to activate this function.

· Tailback Assist (SBC™ Stop) can be activated using the cruise control lever when the vehicle is at a standstill or travelling at a maximum of 15 km/h. The advantage of this is that in stop/go traffic the driver only needs to use the accelerator; when the driver takes his or her foot off the accelerator, SBC™ brakes the SLR to a standstill with constant deceleration. Tailback Assist can remain active up to a speed of 60 km/h. It is automatically deactivated at higher speeds. When Tailback Assist is activated, the letters "SBC S" appear in the instrument cluster.

Ceramic brake discs for top performance

Mercedes-Benz has optimised the outstanding properties of the Sensotronic Brake Control system in the new SLR with a braking system which also marks a technological high-point in a high-performance car: at the front and rear axle of the cutting-edge swing-wing door vehicle, brake discs made from fibre-reinforced ceramic ensure reliable deceleration. Their development is based on the one hand on the results of DaimlerChrysler materials research and on the other on Mercedes-AMG's experience of high-tech brakes in touring cars and GT sport. Here Mercedes-Benz yet again underlines its leading role in the development of groundbreaking technologies for car production.

In manufacturing the brake discs, the carbon fibre, powdered carbon and resin are pressed into shape at high pressure and baked with a silicon infiltration at temperatures of around 1500 Celsius to form the ceramic. The advantages of this composite material are considerable: in addition to being characterised by an extremely sensitive response, the Mercedes-Benz SLR McLaren's brake discs demonstrate a high temperature-resistance of up to 1000 Celsius, which produces a fade-resistance when braking at high speed never before achieved in a series-produced car. The result is brake power of up to 2000 hp. Further advantages of the new brake material include...

· ... the long life of the brake discs – up to 300,000 kilometres.

· ... the low maintenance requirements of the corrosion-free brake discs.

· ... the lower weight – up to 60 percent less than conventional brake discs – a further bonus in terms of dynamic handling and ride comfort.

· ... even more comfortable braking – the low thermal expansion of the ceramic discs means reduced heat friction under high stress. Cold friction, familiar from cast iron brake discs, is also significantly reduced with ceramic brakes.

Brake pad area of 440 cm2 at the front axle